- CementDEC® 3K

- FlexDEC® 2K

- EpoxyDEC® 2K

- TopcoatDEC® AS-2K

- TopcoatDEC® SF-2K

- EpoxyPRIMER® 2K

- CementDEC® 3K

- FlexDEC® 2K

- EpoxyDEC® 2K

- TopcoatDEC® AS-2K

- TopcoatDEC® SF-2K

- EpoxyPRIMER® 2K

TopcoatDEC® SF-2K

Unieke satijnen afwerking Volledig alifatische polyurethaan topcoatOp waterbasis speciaal ontwikkeld voor de bescherming van epoxy- en polyurethaan self-leveling vloeren

TopcoatDEC® SF-2K Speciaal samengesteld polyurethaan op waterbasis voor vloerbescherming bestaat uit twee componenten.

TopcoatDEC® SF-2K Volledig alifatisch, speciaal samengesteld door onze revolutionaire, op polyurethaan gebaseerde vloerbescherming topcoat van ANILO®. Het is een twee componenten, A+B comp.

Volledige alifatische coating met uitzonderlijke prestaties in een groot aantal toepassingen. Het product wordt sterk aanbevolen voor de bescherming van epoxy- en polyurethaan gietvloeren.

TopcoatDEC® SF-2K Protec heeft uitstekende zonlicht-, chemicaliën-, water- en zeer hoge slijtvastheid. Het product heeft een uitstekende weerstand tegen vlekken.

Aanbrengen gebeurt met een roller, met een verbruik van 80-100 gr/m² (één laag).

- Kenmerken & Voordelen

- Polyurethaan basis

- Geschikt voor toepassing in gesloten ruimtes.

- Veilig en niet-ontvlambaar (nul VOC).

- Volledig alifatisch and op waterbasis

- Niet giftig

- Hoge slijtvastheid

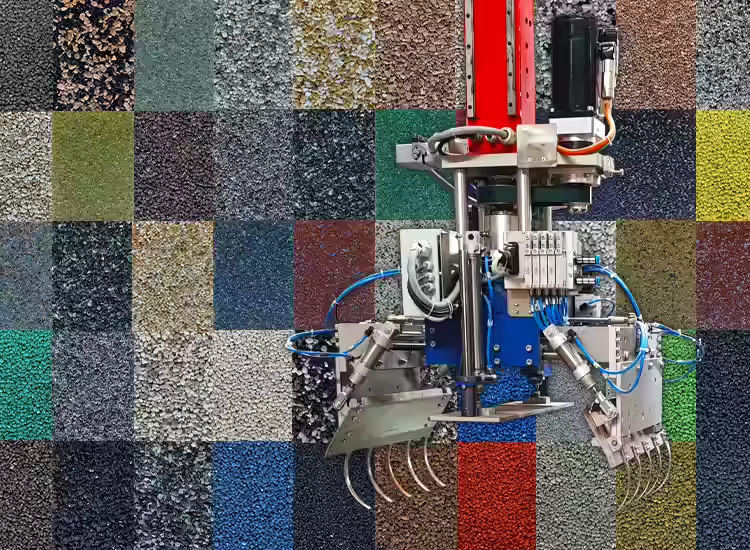

- Oppervlaktebescherming voor open poreuze korrels

- Geen verkalking of chloorvlekken door constant watercontact.

- Uiterlijk na uitharding: SATIJNMAT uiterlijk na droging en vertoont geen lichtreflecties.

- Epoxy en polyurethaan self-leveling laatste beschermlaag

- Steentapijt open poreuze laatste beschermlaag

- Uitstekende sterke hechting

- Uiterlijk na uitharding: MAT uiterlijk na droging en vertoont geen lichtreflecties.

- Lange verwerkingstijd

- Uitstekende hechting tussen de lagen

- Sterke hechting

- Unieke satijnen afwerking

- Uitstekende zonlicht bestendigheid

- Eenvoudig aan te brengen

- Snelle uitharding

- Oppervlaktebescherming voor polyurethaan en epoxy voor gietvloeren.

- UV-beschermende (gepigmenteerde) laag voor self levelling

- Self levelling laatste beschermlaag voor parkeergarages.

- Industriële epoxyvloeren laatste beschermlaag

Minimaal verbruik 80-100 gr/m².

Maak de ondergrond en het oppervlakte stof volledig schoon.

Mengen; Gebruik een mixer met lage snelheid (300 tpm). Voeg de tweede component toe en blijf gedurende 3 minuten mengen.

Toepassing; Aanbrengen met roller. Zorg ervoor dat het aangebrachte materiaal niet door overmatige rollen wordt verstoord, aangezien er rol sporen kunnen verschijnen. Het materiaal droogt relatief snel en daarom zal bij extra walsen na de eerste toepassing oppervlakte defecten optreden. Als er een tweede laag wordt aangebracht, zorg er dan voor dat de eerste laag volledig droog is voordat de tweede laag wordt aangebracht. Voor de bescherming van microcement- of self leveling mortel oppervlakken wordt aanbevolen een eerste laag SmartTOPCOAT® AS-2K Anti-Stain aan te brengen als doordringende afdichting.

Schoonmaak; Gereedschappen en apparatuur reinigen met water.

Bereken Verbruik & Vraag een Offerte aan

Bereken nu

TDS

TDS