- CementDEC® 3K

- FlexDEC® 2K

- EpoxyDEC® 2K

- TopcoatDEC® AS-2K

- TopcoatDEC® SF-2K

- EpoxyPRIMER® 2K

- CementDEC® 3K

- FlexDEC® 2K

- EpoxyDEC® 2K

- TopcoatDEC® AS-2K

- TopcoatDEC® SF-2K

- EpoxyPRIMER® 2K

CementDEC® 3K

Hoogwaardig beton vloersysteemPolyurethaanbasis voor industrieel self-leveling vloersysteem Uitstekende hechting op alle bouwmaterialen

CementDEC® 3K Polyurethaanbasis Speciaal samengesteld met cement gebaseerde mortel voor self-leveling vloersystemen. Voor versleten en oude vloeren Hoge prestaties bij alle industriële vloer toepassingen. Excellentie, hoge hardheid en druksterkte (>70 MPa).

CementDEC® 3K wordt aanbevolen voor omstandigheden die maximale mechanische sterkte en uitzonderlijke weerstand tegen fysische en chemische stoffen vereisen; Het gebruik van een topcoat is optioneel vanwege het ongelooflijk gladde oppervlak na het aanbrengen. indien gewenst: Wij raden onze volledig alifatische watergedragen TopcoatDEC® SF-2K aan als toplaag.

CementDEC® 3K is een niet-giftig product bij contact met voedingsmiddelen en drinkwater. Het kan binnen en buiten worden gebruikt; bij buitentoepassing wordt een lichte verkleuring verwacht. indien gewenst: Wij raden ons volledig alifatische watergebaseerde TopcoatDEC® SF-2K-product aan voor 100% weerstand tegen zonlicht bij buitentoepassingen.

- Belangrijk Kenmerken

- CementDEC® 3K Polyurethaanbasis

- Snelle uitharding

- Fast curing

- Warm Waterbestendigheid (80 °C - 100 °C).

- Uitstekende biologische en chemische resistentie.

- Toepasbaar op vochtige ondergronden.

- Niet giftig

- Hygiënisch materiaal

- Bestand tegen negatieve hydrostatische druk.

- Uitstekende hechting op alle bouwmaterialen

- Hoge slagvastheid

- Slijt- en krasbestendigheid

- Hoge chemische bestendigheid

- Minimale krimp

- Stevige, monolithische, slijtvaste laag.

- Geeft een glad oppervlak en het gebruik van een topcoat is optioneel (zie hierboven)

- Bestand tegen een breed temperatuurbereik, niet brandbaar.

- Zware industriële vloeren

- Bescherming van industriële vloeren

- In de voedingsmiddelen- en drankenindustrie

- Chemische industrievloeren

- Apotheek vloeren

- Zorgv loeren

- Elektronicawinkelvloeren

- Machinebouwvloeren

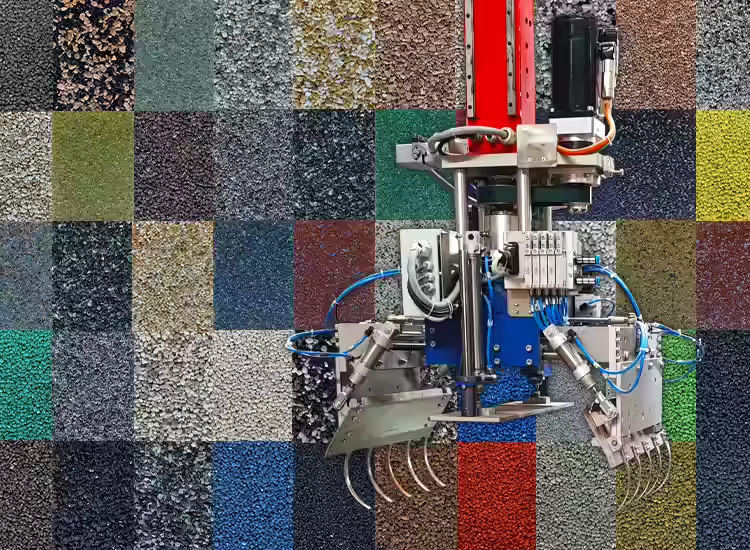

- Antistatische, vonkvrije, antislip, antibacteriële, stofvrije en decoratieve coatings.

Indicatief is een dictaat van ongeveer 2 kg/m²/mm.

Reinig het oppervlak indien mogelijk met een hogedrukreiniger. Verwijder olie-, vet- en was verontreinigingen. Cementhuid, losse deeltjes, losmiddelen en uitgeharde membranen moeten eveneens worden verwijderd. Het applicatie oppervlak moet droog zijn.

Primer; Primer is vereist vóór het aanbrengen van watergedragen EpoxyPRIMER® 2K.

Mengen CementDEC® 3K Meng (Deel/C cement gebaseerde mortel en op polyurethaan gebaseerd deel/B Meng delen gedurende 2 minuten) en voeg vervolgens deel A toe. Meng gedurende 3 minuten totdat de vloeistof homogeen wordt. Gebruik een langzame spiraalmixer (150-200 tpm). Het consistente mengsel moet worden uitgesmeerd tot een aanbevolen dikte van 4-8 mm, zodra het mengen goed is uitgevoerd. Gebruik een stalen troffel om de nieuwe coating glad te maken. Gebruik een prikroller om de gesloten gassen vrij te maken.

Schoonmaak; Reinig uw gereedschap en apparatuur tijdens de applicatie fase met Cellulose Thinner.

Bereken Verbruik & Vraag een Offerte aan

Bereken nu

TDS

TDS